We got 7 inches of rain in a hurry from Isabel, along with enough wind to take down a LOT of trees and leave most of the county in the dark. Don't know that we're "truly good" at the "art", but it's a lot like sweating copper pipes, strikes me as uncomplicated. I'd do it again, considering how little time was involved. But it hasn't been a problem, hasn't cracked, hasn't leaked, and I liked the appearance. Necessary? Apparently not from what you're saying. This is a test? For instance, we soldered the tops of the seams where the pans went under siding rather than mashing the seams flat. Where is that applicable? I can think of very few instances where the soldering equipment comes out on a standing seam roof.) Soldering is an art and there are too few that are truly good at it. ( Thinking back to your post, you mention soldering the tops and bottom of standing seam pans where applicable. No suggestion made that we knew all that was entailed. Actually, what I said was that my buddy got 5 minutes of instruction and had at it. I don't often know where they are, but I'm pretty sure they always know where I am. Not knowing them or not following them usually leads to heartbreak. I agree that standing seam is not brain surgery, but there are rules just as in any other building operation. I also run across numerous burst solder joints ( Thinking back to your post, you mention soldering the tops and bottom of standing seam pans where applicable.

Not near as easy as pulling a few shingles.

The difference between a leaky shingle roof and a leaky standing seam roof is the difficulty in taking seams back apart. There were a few simple rules he didn't follow. I'm doing extensive (and expensive) repairs to an 8 year old standing seam roof done by someone who had quite a bit more than 5 minutes of instruction.

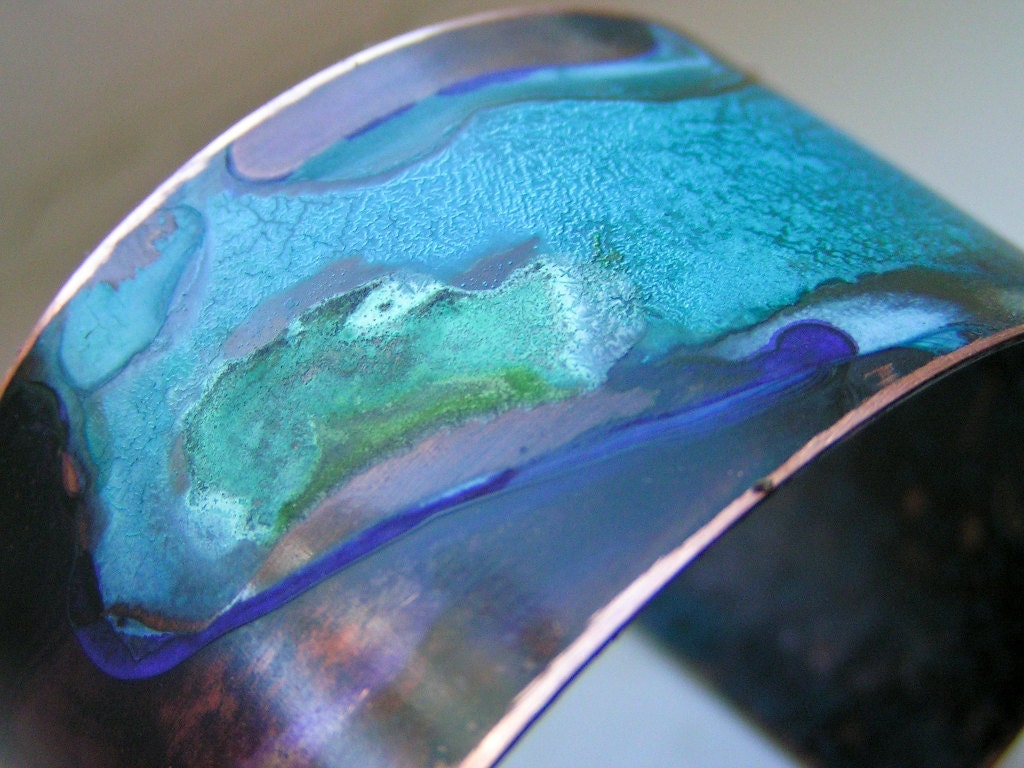

COPPER PATINA GREEN RECIPE INSTALL

Telling that guy "5 minutes of instruction " is all that's needed to install a standing seam roof is like telling someone that wants to learn to play the flute to "blow in it and move your fingers up and down the outside". I agree with some of your points about standing seam, but then you're probably smarter than the average bear. Then change for variety.Ĭopper strikes me as the obvious inexpensive choice for maintenance-free exteriors, even if it doesn't turn green here.PAHS Designer/Builder- Bury it! We do a 2 person crew, one up and one down. Bring your own fall protection as it's 40' up (down?) on one end and be ready to sign a waiver. I've got one coming up if you want to come help. And Isabel, directly overhead, didn't lift it. Once did tapered pans for a tapered roof. We solder tops and bottoms of the pans where applicable. The seamers and pan former self-align so it's really tough to screw up. As my buddy and I aren't roofers, we figure it's as fast as nailing asphalt shingles would be.

Over the years I've gotten a huge load of crap from roofers about how difficult it is to do a traditional standing seam. My first roof was done with a luthier buddy who bought some used seamers, got 5 minutes of instruction, and went to work on his place. I have two choices, both deliver from an hour away, Richmond and Lynchburg. Rolls for roofing, usually 500 lbs (1000 lbs is heavy to handle), widths vary. We use 3'x10' sheets for siding, attached with copper rivets. Tom, how do you buy your copper? In a roll? Sheet? What weight? Where?

0 kommentar(er)

0 kommentar(er)